How Does Machine Vision Improve Quality Control in Automated Manufacturing?

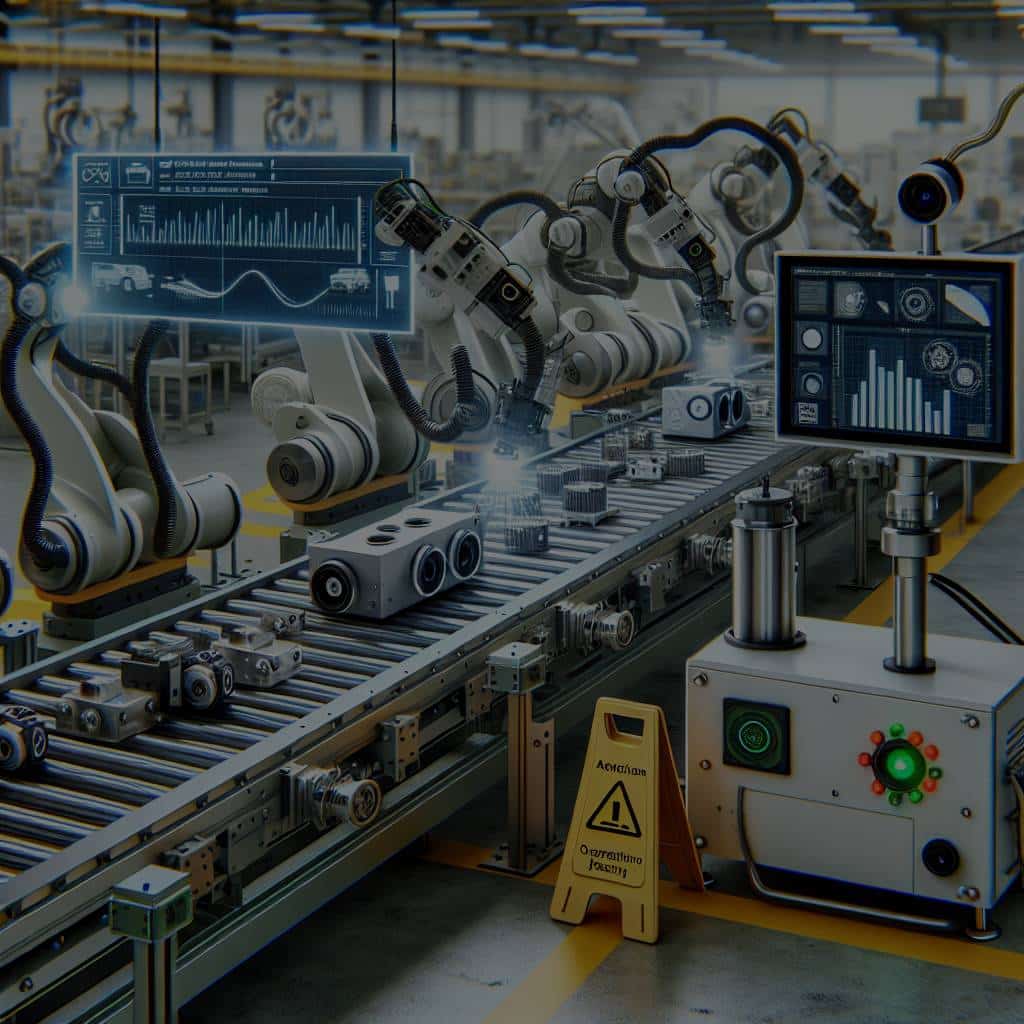

When you think about quality control in manufacturing, what comes to your mind? Perhaps, you envision a team of meticulous human inspectors examining products as they roll off the assembly line. However, in today’s technology-driven industrial environment, the process of quality control has evolved significantly. Machine vision, an innovative technology, is transforming traditional quality control systems. It is enhancing accuracy, speed, and efficiency, thus making a significant impact on various industries.

Bringing Machine Vision into Focus

Machine vision is a technology that enables computers to visualize, process, and understand the physical world. It uses an array of cameras, sensors, and machine learning algorithms to capture and analyze images in real time. This next-generation technology is revolutionizing industrial inspection processes, allowing for unprecedented levels of precision and speed.

Avez-vous vu cela : Can Electrochromic Smart Windows Significantly Reduce Building Energy Consumption?

From automotive to pharmaceuticals, electronics to food and beverage, machine vision systems are being leveraged across a spectrum of industries for a variety of applications. The primary use, however, remains in ensuring impeccable quality control in automated manufacturing processes.

The Role of Machine Vision in Quality Control

Quality control is a critical aspect of any manufacturing process. It entails checking products for defects and deviations from predefined quality standards. In the past, this was a manual, time-consuming process that was fraught with human error. But today, machine vision has emerged as a game-changer.

Sujet a lire : Explore the wonders of mystery box deutschland today!

Machine vision systems can inspect products at a speed and accuracy level that is far beyond human capabilities. They can process vast amounts of data in mere seconds, identifying even the slightest variations or defects in products. Machine vision doesn’t just increase the speed of quality control processes, it also significantly reduces errors and boosts overall production efficiency.

Moreover, unlike human inspectors, machine vision systems can work round the clock without fatigue or loss of focus. This means that quality control can now be a continuous process, ensuring the consistent quality of products.

Transforming the Manufacturing Industry with Machine Vision

Machine vision is not just transforming quality control, it is reshaping the entire manufacturing industry. By integrating machine vision systems into their production lines, manufacturers can increase throughput, reduce waste, and significantly boost their bottom line.

One of the key advantages of machine vision is its ability to generate vast amounts of data. This data can provide valuable insights into the manufacturing process, helping manufacturers identify bottlenecks, streamline their operations, and optimize production processes. Additionally, this data can be used to predict maintenance needs, reducing downtime and increasing the overall efficiency of the production line.

Machine vision also enhances traceability in the manufacturing process. By capturing and storing data at every stage of production, it provides a detailed record of the manufacturing process. This not only helps in quality control but also aids in compliance with regulatory standards.

Taking Quality Control to the Next Level with Machine Vision

The power of machine vision goes beyond just identifying defects in products. It can also predict potential issues before they occur, taking quality control to the next level.

By analyzing data from past inspections, machine vision systems can identify patterns and trends, predicting potential manufacturing defects. This allows manufacturers to address issues at their root cause, preventing defects before they occur.

Moreover, machine vision can also help in improving product design. By analyzing data from quality inspections, manufacturers can gain insights into how their product design could be improved, leading to better quality and more efficient production processes in the future.

Machine Vision: A Key Driver of Industry 4.0

In the era of Industry 4.0, machine vision is emerging as a key driver of industrial transformation. It is integrating with other advanced technologies like artificial intelligence, robotics, and Internet of Things (IoT) to create smart factories where production processes are fully automated, highly efficient, and supremely accurate.

In these smart factories, machine vision systems inspect products, robots handle materials, and IoT devices monitor and control the production environment. All these technologies work in harmony, driven by a common goal – to deliver high-quality products in the most efficient manner.

As more and more manufacturers embrace Industry 4.0, the role of machine vision in quality control is set to become even more pivotal. Its ability to ensure consistent product quality while driving efficiency and profitability makes it an indispensable tool in the modern industrial landscape.

In this age of rapid technological advancement, machine vision is not just a futuristic concept, but a present-day reality that is making quality control more efficient, accurate, and reliable than ever before. It is not just changing how we inspect products, but how we design, manufacture, and deliver them. It is, in essence, redefining the very concept of quality in the manufacturing industry.

Deep Learning and Its Role in Machine Vision Quality Control

Deep learning is a subset of machine learning that uses algorithms to model high-level abstractions in data. It plays a significant role in enhancing the capabilities of machine vision. By training machine vision systems using deep learning techniques, the ability to recognize patterns, understand context, and make informed decisions can be greatly improved.

Deep learning models can learn from vast amounts of data, making it possible for machine vision systems to identify complex patterns and correlations that would be impossible for human inspectors to discern. This ability to learn and adapt makes deep learning-powered machine vision systems incredibly effective for quality control in manufacturing.

For instance, with deep learning, vision systems can be trained to recognize different types of defects in products, even those that are not visible to the human eye. This level of precision in defect detection can significantly reduce the occurrence of false positives and negatives in quality control processes, leading to enhanced accuracy and efficiency.

Furthermore, deep learning can enable vision systems to adapt to variations in product design or changes in the manufacturing process in real time. This adaptability allows for continuous improvement in quality control, ensuring that the highest quality standards are maintained at all times.

Notably, deep learning can also enhance decision-making capabilities of machine vision systems. By analyzing historical quality data and correlating it with real-time inspection data, these systems can predict potential defects and suggest corrective actions, even before a product leaves the assembly line. This predictive capability can save manufacturers from costly recalls and reputational damage, making deep learning a game-changer in quality control manufacturing.

Conclusion: Embracing Machine Vision for Quality Control

The impact of machine vision on quality control in automated manufacturing is indeed profound. With its ability to deliver consistent, accurate, and efficient quality inspections, machine vision is transforming the manufacturing industry. Its ability to work tirelessly, adapt in real-time, and predict potential issues elevates quality control processes to a whole new level.

The incorporation of deep learning further enhances the capabilities of machine vision systems, making them more intelligent and capable of making informed decisions. As such, manufacturers that leverage this technology can maintain higher quality standards, improve productivity, and increase their bottom line.

As we progress further into the era of Industry 4.0, the integration of machine vision into quality control processes is becoming more of a necessity than a choice for manufacturers. It offers a promising solution to the challenges of maintaining product quality in a fast-paced, high-volume, and high-variety production environment.

In essence, machine vision is redefining the very concept of quality in manufacturing. From detection of defects to ensuring compliance with quality standards, from real-time decision making to predictive maintenance, machine vision is revolutionizing every aspect of quality control. By embracing this transformative technology, manufacturers can not only improve their product quality but also gain a competitive edge in today’s fiercely competitive market. Machine vision is no longer a futuristic concept, but a present-day reality that is transforming the world of manufacturing.